Yesterday rather than the usual daily grind I went over to Sadler's Ales in Stourbridge for a Brew A Beer Day (it was a Christmas present). It turned out to be rather more hands-on than I expected and was immense fun. As someone who enjoys beer, it was fascinating to get involved with the process and to chat with a brewer.

Time to mash

The day kicked off by meeting up with two other people which were on the same event: Martin and Peter. We didn't know each other before hand and had all been given the experience as a present.

All beer starts off with malt, malted barley to be precise.

Our first order of the day was to mash 300kg of malted barley with around four barrels (a barrel is 147l) of water at 71c in the mash tun. The mash is essentially a porridge, which extracts the sugar from the barley and also converts the starch in the barley to sugar. Malted barley has started to germinate and has present the enzymes needed to convert starch to sugar.

Barley can be roasted (a bit like coffee), in different grades: caramalt, chocolate malt, etc. This roasting gives the malt a dark colour and a caramel to bitter taste. A pale ale is made using just plain malt, other malts are added to create amber ales, porters and stouts. A stout would have a proportion of chocolate malt. We were brewing an amber ale which had 25kg of caramalt in it. There is also a small proportion of Wheat added, this helps in forming the head of the beer.

This involved loading 300kg of malt into the mash tun, in 25kg sacks. Each sack had to be lugged up a ladder and poured in to a hopper. The hopper helps to evenly mix the malt with the hot water.

The mash is left for 1 hour to steep, giving us time for breakfast and a beer.

Tapping the wort

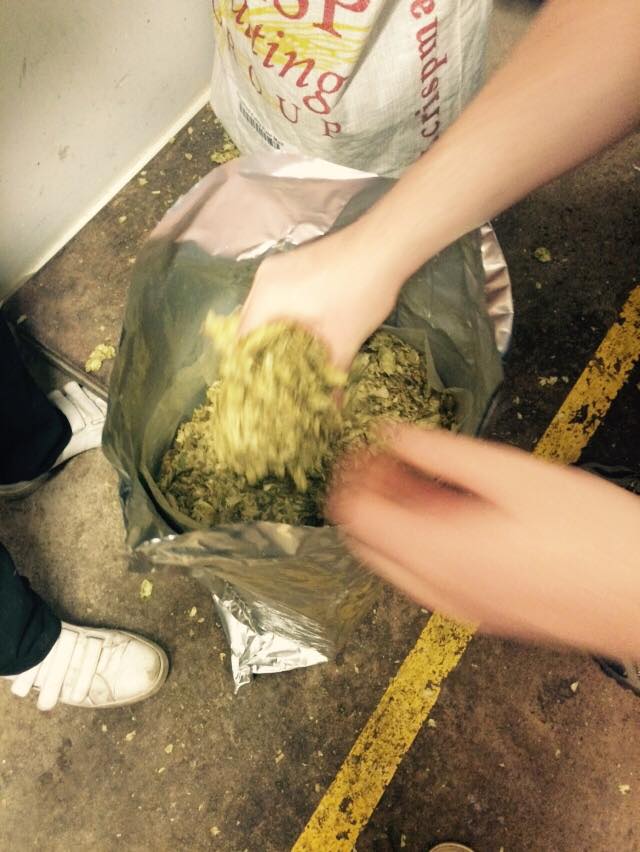

After breakfast it was time to extract the wort (the liquid from the mash) from the mash and transfer it to the kettle. The wort is boiled up with hops added for bitterness and aroma. The mash is also sparged during this process, a sparge arm rotates around the mash tun drizzling hot water over the mash, this further extract more sugar from the malt.

At this stage the wort is surprisingly sweet, an almost syrup like consistency, with malty overtones.

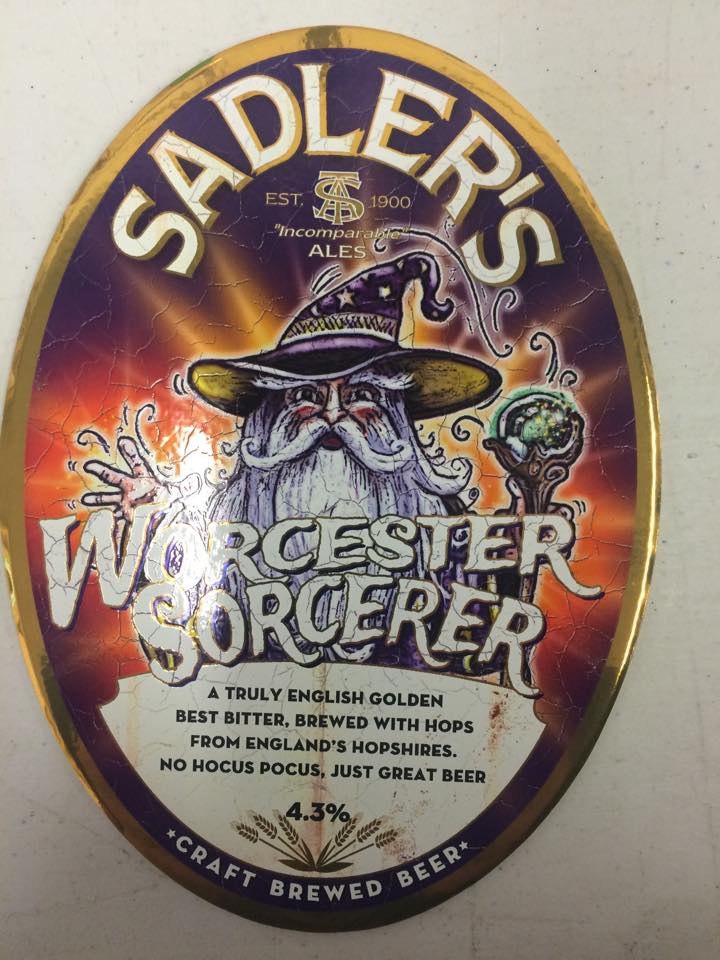

Whilst the pump was busy transferring the wort into the kettle, it was time to prepare the hops. After malt, hops is the other key ingredient in beer, providing all the bittering and aroma. Different varieties of hops and hops from different climbs vary in the level of bitterness and in aroma.

The hops came vacuum packed, so we needed to flake the hops whilst weighting it. It was surprising how sticky our hands were after this, covered in a kind of green resin, smelt rather good though!

Emptying the mash tun

With all the wort extracted from the mash, it was time to empty the mash tun. That involved shovelling out 300kg of wet barley into sacks. Not particularly glamorous and a bit of hard work, but fun all the same.

With the mash tun empty and the wort busy getting up to boiling point, it was time to sit down and relax over lunch, and some more beer.

Adding the hops

Lunch over, it was time to add the hops to the boiling wort. Hops is added at various times during the boiling. Hops added early on (and boiled up for a while) adds bitterness to the beer. Hops added late on adds aroma to the beer. We were brewing a golden beer, which had about 3kg of bittering hops added early on and 5kg of aroma hops added late on.

The brew house was filled with a wonderful aroma when the hops was added.

Fermenting

With the wort all boiled and infused with the hops, it is time to transfer to the fermentation vessel. Over three days in the fermentation vessel the yeast will turn the sugar into ethanol!

Having just been boiled the wort is rather hot, far to hot to add the yeast directly too. The wort is pumped through a heat exchanger en-route to the fermentation vessel. Cold water is pumped through the other channel of the heat exchanger. This results in a quickly cooled wort at 20c and hot water at 71c ready for the following days brew.

The final and somewhat critical step is to add the yeast.

The last and by far the least enviable task is to clean out the kettle, thankfully we were spared that job. To be honest I'm not sure I'd be able to get in through the opening to clean it out.

Pulling my first pint

At this point, I can safely say, I've (helped) brewed roughly 3,000 pints of beer. With the yeast bubbling away in the fermentation vessel, we retired to the bar for a farewell pint and I got chance to pull my first pint (well a half actually)

All in all, I had a wonderful day, it was fun all around and I learnt a fair bit too. The people at Sadler's Ales were really friendly and made it an excellent day. I'd recommend it to anyone who likes beer, or as a present to anyone who knows someone who likes beer.